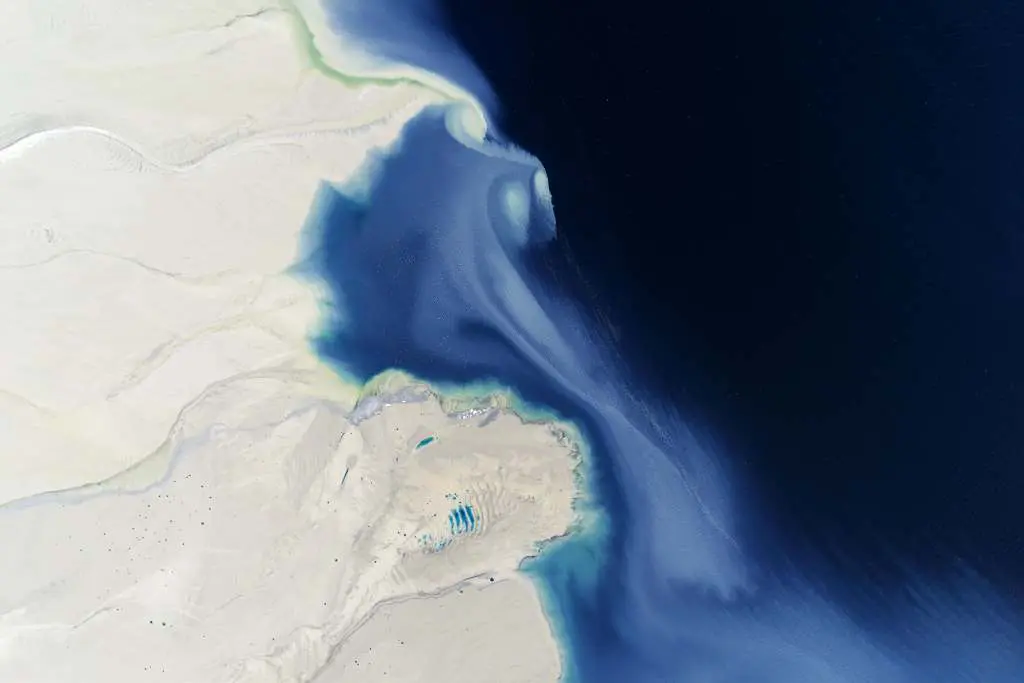

Leading mineral processing & materials handling solutions for world class mining operations

High throughput, energy-efficient systems engineered with compact, low-head circuits and plant layouts that commission faster, run safer and deliver predictable performance, when compared to traditional fixed plant arrangements.

Engineered systems that perform in the real world

Delonix Solutions designs and delivers crushing, screening, comminution and conveying systems for global mining operations, integrated with ROM walls, stockpiles and ore reclaim into one engineered solution and one coordinated plant layout. All tailored to your ore characteristics, site and operating strategy.

Supporting both greenfields developments and brownfields upgrades, our focus is high throughput, compact, low-head circuit layouts that provide safe access, reliable performance and easy maintainability. From early studies and commissioning through to ramp-up and steady-state production, we set the plant up to achieve nameplate quickly, operate predictably and maintain energy-efficiency over the full life asset.

Capabilities & what we deliver

We provide end to end capability across the mining value chain, including:

Compact layouts that reduce cost & complexity

We design and engineer compact, low‑head circuit and plant configurations to reduce structural complexity and working‑at‑height risk.

Primary crushing circuits can be configured with ROM wall heights of less than 12m while achieving and maintaining high throughput of up to 52mtpa.

Shorter structures and optimised plant layouts reduce steel and concrete quantities, reduce power requirements and improve energy efficiency over the asset life.