Behind the scenes at Kansanshi: The engineering partner you didn’t know was there

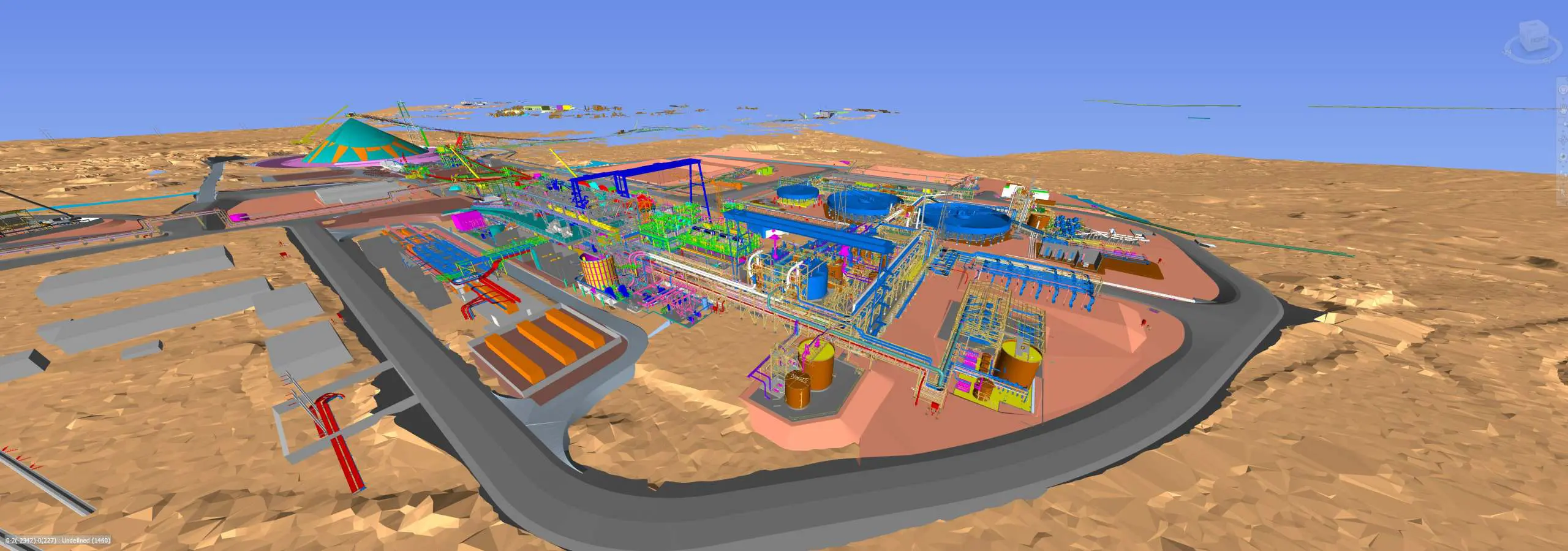

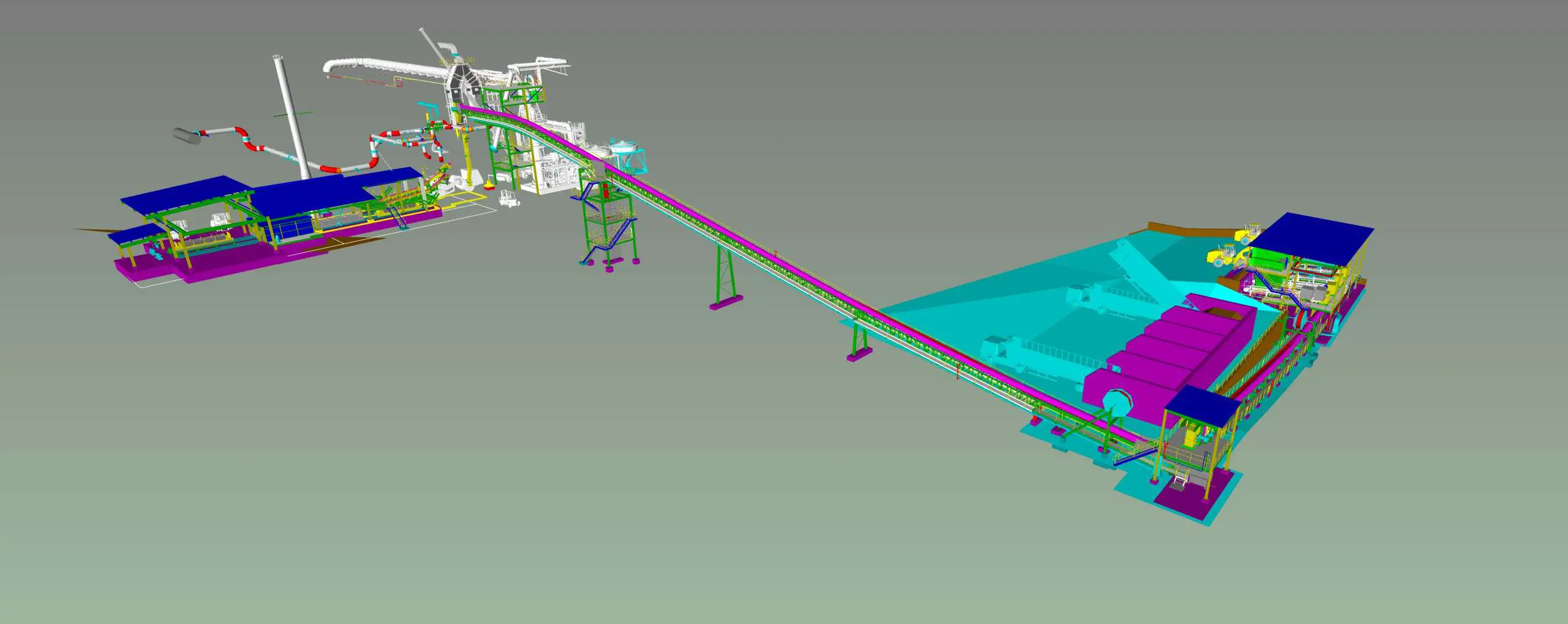

Birds-eye view of the Kansanshi operation’s S3 expansion and upgrade of the flotation circuit.

Cop-per load of this

When it comes to copper mining engineering projects, the big names often dominate the conversation. However, it’s the detail behind the design, the ingenuity in the integration and the rigour in execution that tell the real story.

At Kansanshi, Africa’s largest copper–gold operation, one company has been working steadily behind the scenes for more than a decade. That company is Delonix Solutions.

From flotation circuit upgrades and modular crushing systems to full infrastructure expansions, Delonix Solutions has been a trusted partner to First Quantum Minerals (FQM), even when our name isn’t always on the marquee.

A long view of value: 10+ years with First Quantum Minerals

Our journey with Kansanshi’s copper mining engineering projects began in 2012. Not as headline designers – but as specialists brought in for what we do best. These encompass clever, lean and purpose-built design in difficult conditions.

Since then, a series of projects that showcased the full range of our expertise starting with civil, structural, platework and concrete engineering.

Today, we deliver full structural, mechanical, piping (SMP), electrical and civil projects, often done in close collaboration with major consortia including CPC Engineering, FLUOR and others.

Altogether, these layered partnerships reflect the complexity of contracting in mining and the value of engineering firms that quietly deliver, again and again.

Smelter feed upgrade: compliance and community in copper mining engineering projects

In the early 2010s, the Zambian Government introduced measures targeting the export of copper concentrate. The aim was to promote domestic processing and value addition.

The goal was simple: more value retained in-country, higher returns for national development.

Delonix Solutions, working with FLUOR, designed the furnace feed system with the latest ISACONVERT™ technology. As a result, this helped FQM align with the new national push for improved local smelting capacity.

From stockpile layout to billet casting interfaces and gas scrubbing structures, we delivered a processing plant that met both technical and environmental demands.

Delonix Solutions founding executive director Philippe Vatin, who worked the project at the time, comments on this.

“When you’re working on infrastructure that supports policy change, you’re not just delivering a project,” he said.

“You’re enabling sovereign control over resources. And it’s engineering that matters to people.”

The ISACONVERT™ feed system at the Kansanshi operation in Zambia.

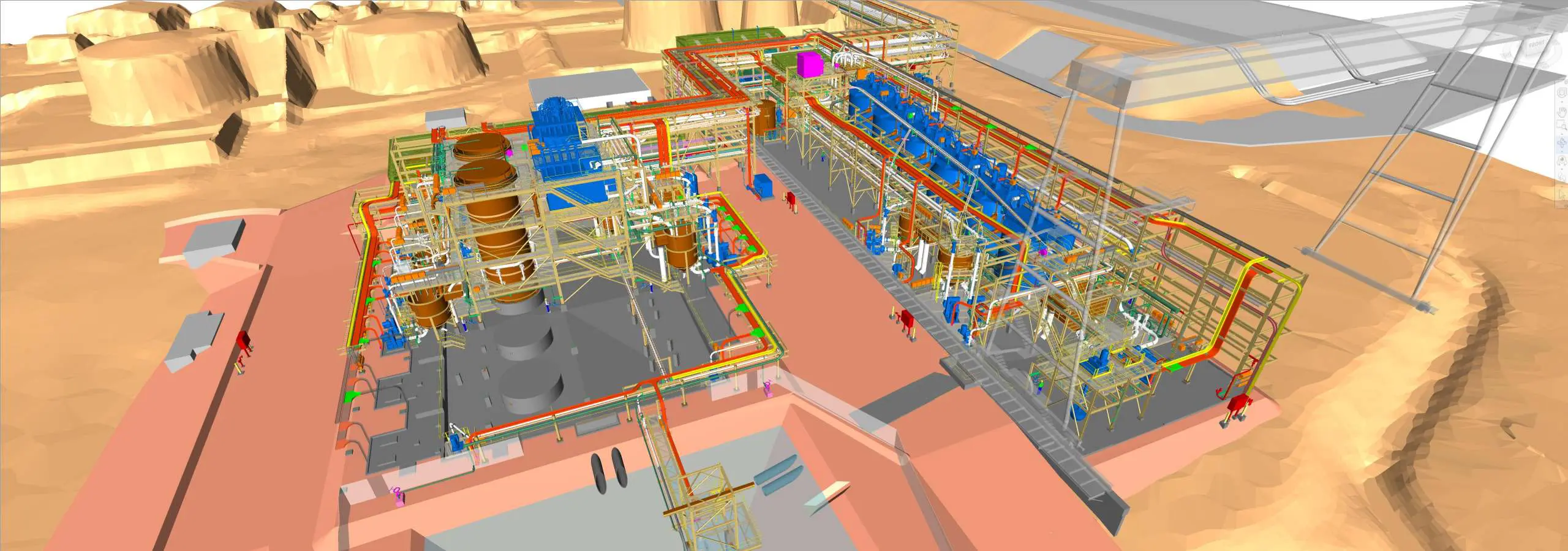

Flotation upgrades: innovating within constraints

The Kansanshi site is tightly packed and heavily utilised, a reality that makes every brownfield upgrade a puzzle in spatial choreography.

Delonix Solutions was brought in to support the civil and structural engineering design aspects of an estimated US$50m flotation circuit upgrade. This included the addition of four flotation cells to improve concentrate quality.

Given the tight space and budget, our team designed a compact structural and concrete solution that slotted into place like a keystone.

FQM supplied the process design; we engineered the fit.

Ultimately, result was higher-grade copper concentrate, improved regulatory alignment and a satisfied client, all without overspending or overdesigning.

Flotation upgrade at the Kansanshi main plant.

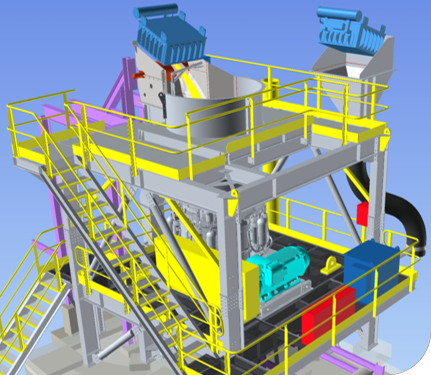

Secondary crusher: competing with time and terrain

Not all problems start with design; some start with underperformance in copper mining engineering projects.

When a previously installed secondary crusher in the oxide circuit by others failed to meet operational expectations, Delonix Solutions was again engaged to redesign the system for reliability and maintainability.

The challenge: replace the crusher in a congested footprint and within a limited shutdown window.

Our response: a modular, preassembled and prewired crusher system, engineered offsite and installed in days.

Because civil and structural works were completed in advance, the full unit was lifted into place with minimal downtime.

“We don’t just compete on quality,” said Mr Vatin.

“We compete on time, on access and on how little disruption we cause to our client’s operations.”

Kansanshi’s secondary oxide crusher upgrade.

S3 Expansion: a complete optimisation effort

2023 | Latest round of copper mining engineering projects at Kansanshi

The Kansanshi S3 expansion was a milestone event, not just for FQM, but for the partners who helped make it possible.

As part of a three-party collaboration with FLUOR and CPC, Delonix Solutions contributed extensively to both wet plant upgrades and non-process infrastructure (NPI):

Wet circuit:

- Structural and concrete design across flotation, thickening and concentrate transport systems.

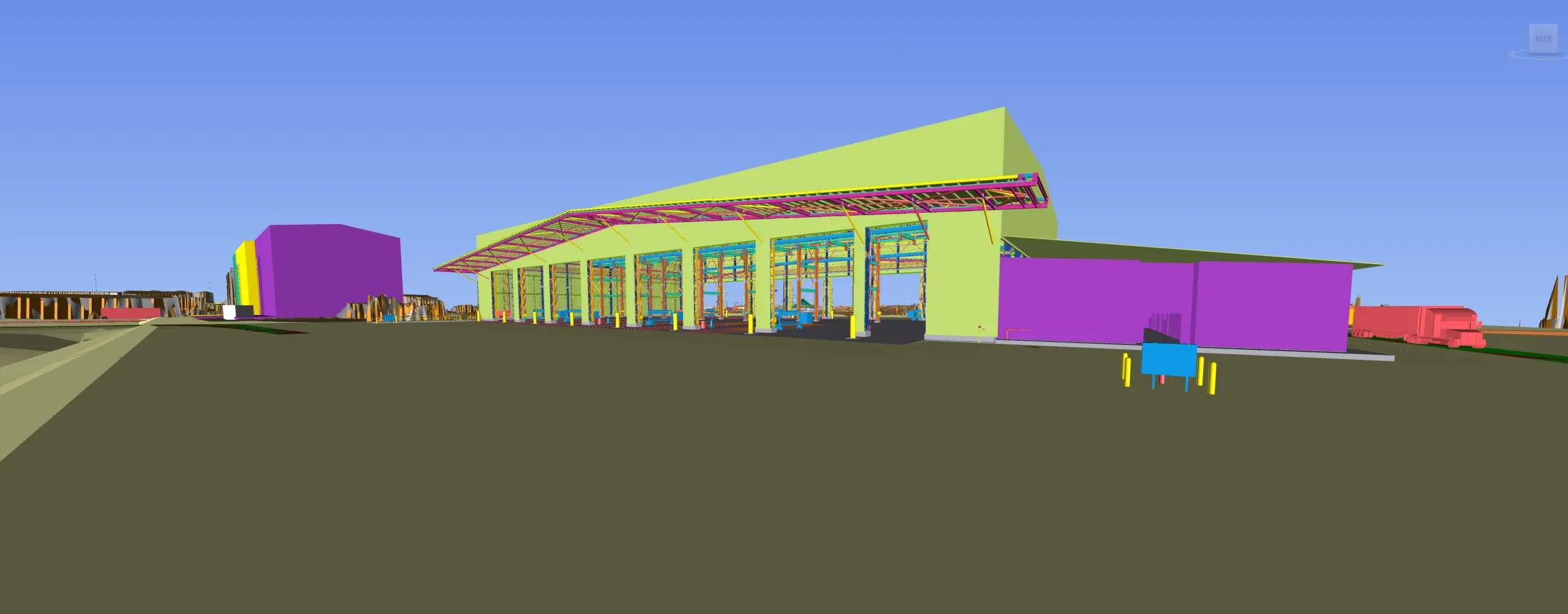

NPI:

- Full engineering delivery of a heavy vehicle workshop, administrative offices, fuel facilities, lubrication systems and more.

Because the site presented terrain challenges, with up to 10m of backfill required in some areas, Delonix Solutions used proven methods to flatten the curve, both literally and figuratively.

Importantly, this wasn’t just project support, it was full-spectrum optimisation of a flagship mine.

Non-process infrastructure (NPI) at the Kansanshi S3 expansion project.

The power of being present in copper mining engineering projects

In a sector dominated by marquee names, Delonix Solutions often works in the shadows as the quietly effective partner trusted to deliver the most critical packages of work.

At Kansanshi, our role has been long-standing, layered and indispensable.

For more than a decade, we have embedded our values in every structure and circuit:

Care, in our alignment with local regulation and environmental responsibility.

Innovation, in how we modularise and integrate in brownfield spaces.

Compete, by delivering faster, safer and smarter than what was done before.

Optimise, through fit-for-purpose engineering that keeps capital lean and operations strong.

Even if we’re not always visible in the project summaries or press releases, our legacy lives in the concrete, in the steel, in the copper and in the daily results FQM sees at Kansanshi.

Accelerate your next copper project. Partner with us now. Contact Fil Resnik here.